Specially developed side-mounted liquid-cooled integrated unit for high-density energy storage application scenarios. Condenses 20 years of practical experience in precision refrigeration. Safe, reliable, highly efficient, and energy-saving.

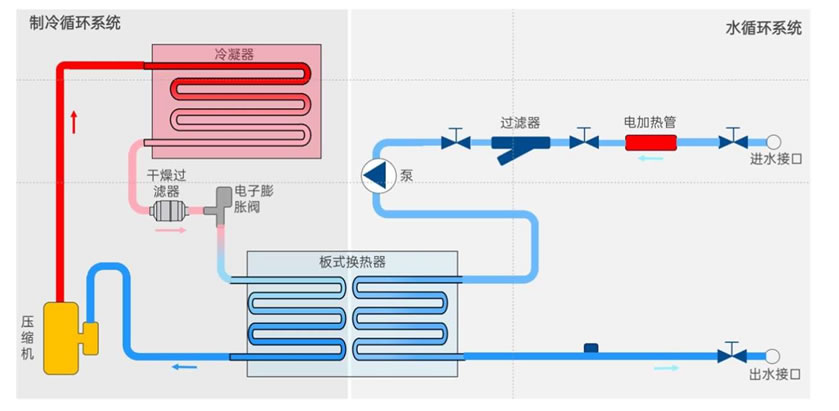

The condenser side releases heat into the air via fans. The unit internally uses a compressor refrigeration system to exchange heat with glycol solution through a heat exchanger. The control system regulates temperature and the circulation flow rate of the water circuit system based on liquid temperature and pressure. The refrigeration side is equipped with a variable frequency refrigeration system. The coolant precisely controls the temperature of battery modules through a plate heat exchanger. Features multiple safety protection designs, supports high-density battery systems, ensuring high efficiency and reliability.

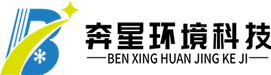

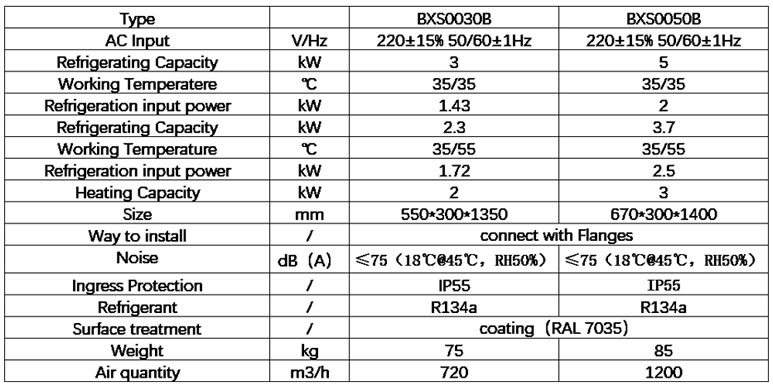

3-5kW air-cooled temperature-controlled unit model and parameters

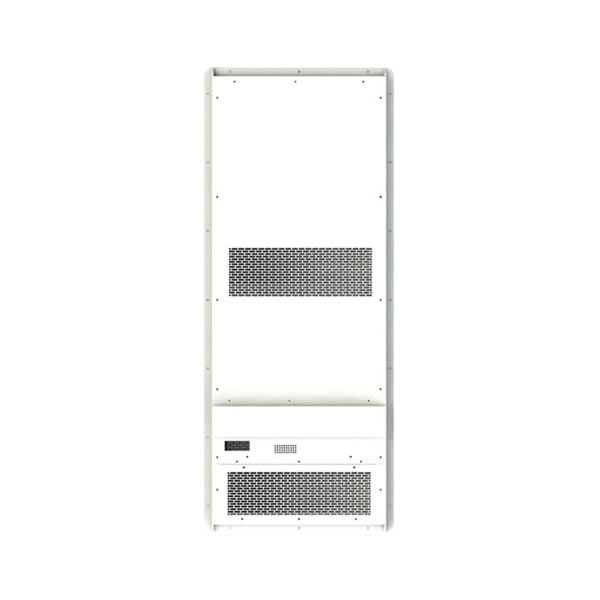

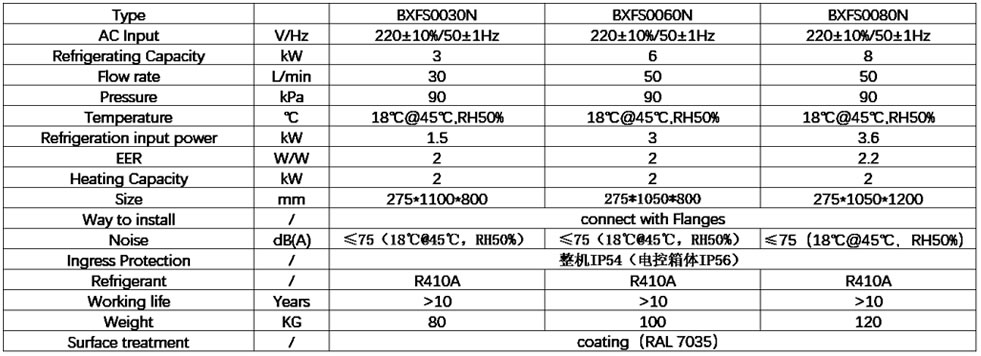

3-8kW liquid-cooled temperature-controlled unit model and parameters

Refrigeration

The water-cooled chiller can set parameters through the display: the start temperature for refrigeration and the stop temperature for refrigeration. When the indoor temperature is higher than the start temperature for refrigeration, the refrigeration begins; when the indoor temperature is lower than the stop temperature for refrigeration, the refrigeration stops. The parameter setting points can be found in the specification manual of the control board.

Heating

The water-cooled chiller can set parameters through the display: the heating start temperature and the heating stop temperature. When the indoor temperature is lower than the heating start temperature, heating begins; when the indoor temperature is higher than the heating stop temperature, heating stops. The parameter setting points can be found in the specification manual of the control board.

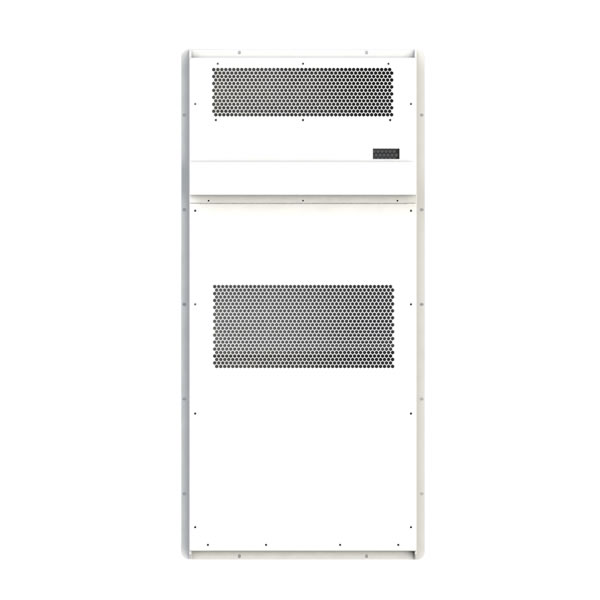

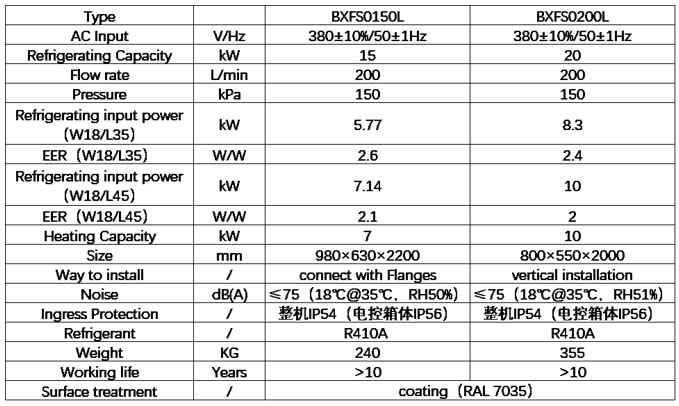

15-70kW liquid-cooled temperature-controlled unit model and parameters

15-70kW liquid-cooled temperature-controlled unit model and parameters